Raychem Industrial Heating Systems represent cutting-edge heat tracing solutions designed primarily for industries such as general processing, oil and gas, chemical, and power generation. Discover more about our comprehensive electrical heat management systems and their operational mechanisms.

Benefits of Raychem Industrial Heating systems

Superior Reliability

RAYCHEM heat trace systems offer high reliability, ensuring uninterrupted operation in critical industrial processes. They are designed for longevity and consistent performance.

High Lifetime Value

These systems offer exceptional long-term value with proven 20+ and 30+ year service life ratings. This longevity is backed by an industry-leading warranty, assuring customers of the product’s durability.

Lower Installed Cost and Cost of Ownership

Despite their superior quality and reliability, RAYCHEM systems are installed at lower costs compared to many alternatives. Additionally, they boast a lower overall cost of ownership due to their long service life and minimal maintenance requirements.

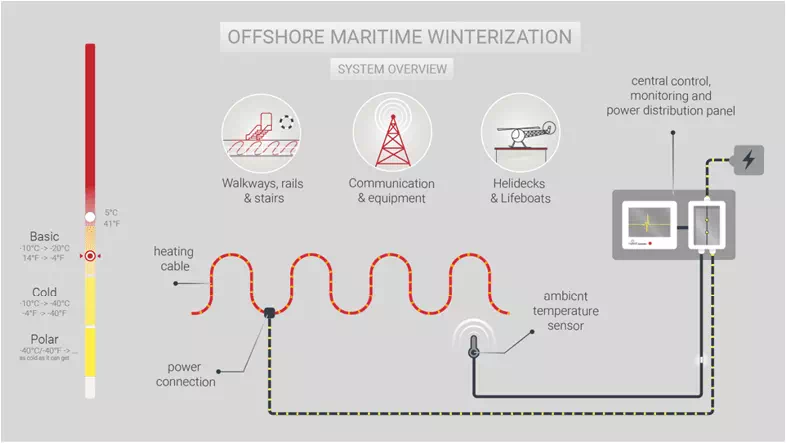

Broad Application Portfolio

The systems cater to diverse verticals, offering versatile applications across various industries. Their easy-to-design and easy-to-install nature contributes to reducing installation expenses.

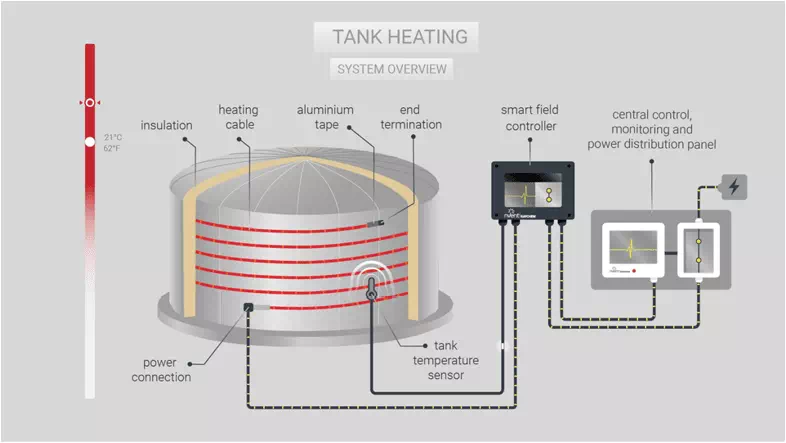

Complete Heat-Trace Systems

Raychem is a technical leader in providing complete heat-trace systems. This encompasses heating cables, components, and controls that are specifically designed and certified as a system. This holistic approach optimizes installation, performance, and ensures worry-free operation.

Expert Support

Customers benefit from expert pre- and post-sale support. The company provides assistance in specification, design, system management, and maintenance. This support ensures that customers receive guidance throughout the lifecycle of the heating systems, from initial planning to ongoing maintenance.